Okay, I've been requested to post this info on cleaning up and reducing trigger pull weight on the newer generation Marlin rimfires (With the T-900 trigger group)

Please bare in mind I am not a gunsmith. This is information I've learned and tried from various other posts on different forums. I won't be held responsible for any injuries/damages that my occur from these modifications. Again, these have worked very well for myself and many other rimfires enthusiasts. My rifles passes every test I can put it through (safety test, various bump tests, etc).

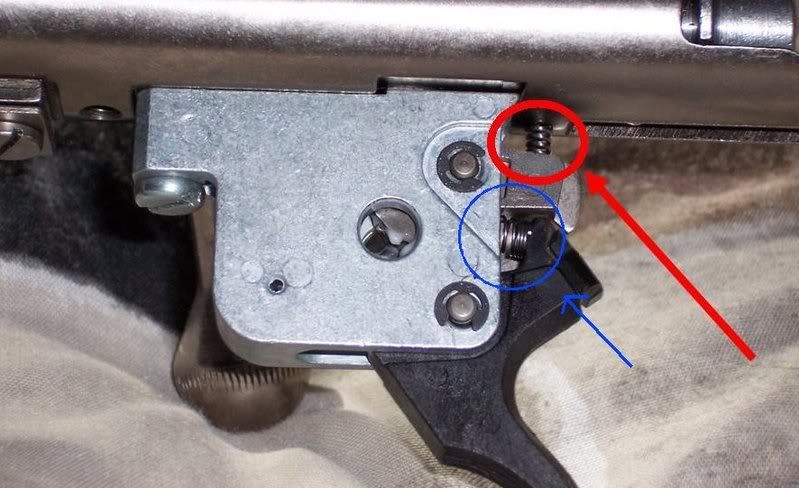

Here is a pic of the T-900 trigger group, with circles around the elements we're going to concentrate on:

The red cirlce is surrounding the firm Sear spring. The upper part of the spring rests against the reciever, the lower part fits well inside a hole drilled into the sear.

The blue cirlce is around the trigger spring. It's responsible for resetting the trigger.

The first, and easiest (non-intrusive) modification is to replace the stock trigger spring with a lighter spring. For reference, in this step you are replacing the BLUE circled spring with a lighter spring.

The cheapest way to do this is to remove a spring from a Bic clickable ball-point pen. A spring from any clickable ink pen should work, however. It can be pretty light, as the main job of this spring is just to re-set the trigger. I advise against going "super" light, however...especially if this is anything more than a benchrest rifle.

Play around until you get the desired tension.

The second step requires STIFFENING the sear spring. For reference this is the spring circled in RED.

The easiest method to do this is to shim the spring slightly. Upon dis-assembly you will see the sear spring seats deeply into a hole in the sear. The shim you will make should fit into this hole, filling it about half-way.

In other words, make a shim to put extra preload on the spring--but keep the shim small enough so the spring can still be held in place by the hole in the sear.

I achieved this by taking a small brass screw, turning down the threads to the correct diameter, and cutting off approximately 1/16" and using this small 1/16" piece of brass as the shim. Since the spring does yield a lot of tension, I recommend you use a HARD nylon or metal for this shim. Brittle plastic can easily break, and wood could easily compress.

To take this one step further, you can use a second spring around the outside of the sear spring to increase the tension further. I chose not to do this on my rifle, as I was more than pleased with the 2lb 7oz. (under 2.5#) trigger. You can use the stock trigger spring (cut in half) around the sear spring if you're cheap. You local hardware store (Ace) probably has a spring that will work.

*Note: Shimming the sear spring will put more tension on the sear as rides against the bolt--therefore making the bolt slightly more difficult to operate. Using the shim alone, it is barely noticeable...however, using a stiffer/second surround spring can make a noticeable difference. Also, be aware if the spring is too thick the sear might no be able to be pulled far enough out of the way in order to completely remove the bolt from the receiver. Test and re-test until you get it right.

I'm not quite sure why shimming the sear spring TIGHTER makes the trigger lighter, but it does.

Finally, I noticed there was quite a bit of side-to-side play between the trigger and the trigger housing...I don't like being able to wiggle my trigger! I fabricated a pair of small shims using brass-stock from feeler gauges I found in my tool-box. You could easily use a thin piece of plastic, or brass shim-stock is available at many hardware stores.

The prior three modifications are all non-intrusive and can easily be swapped back to factory should your rifle not function properly, or not give the desired results. The following is not so forgiving.

While you have your trigger group apart to swap springs, take a fine diamond hone (or 600grit or finer wet/dry paper on a flat surface) and polish the contact surfaces of the trigger/sear. DO NOT remove much material, simply LIGHTLY smooth out the machining marks for smooth engagement surfaces. Removing too much metal, or altering any angles can make for an unsafe condition. I wouldn't recommend doing this step unless you have a lot of confidence, and do THOROUGH SAFETY TESTING afterwards. If you screw something up, you'll be forced to buy new parts from marlin. So err to the side of caution.

Finally, test for proper function of the safety and do several bump tests (unloaded rifle!) with and without the safety on to make sure the rifle will not accidently dischardge.

These modifications will easily yield a trigger in the 2-3lb range, that is crisp and consistent every time...combined with the wide trigger itself, the T-900 trigger group can be an excellent trigger with minimal work.

I've hear reports of some users getting their triggers down to the low 1lb mark. Again, I don't recommend this unless the rifle is a full time, dedicated benchrest shooter. For practical hunting and general plinking, a trigger int he 2-3lb range is more than acceptable.

For what it's worth, my stock trigger averaged 7lb 13oz out of the box...I was able to reduce it safely, to nearly 1/3 of that.

Good luck, be cautious, and enjoy your "new" trigger...it's a much cheaper alternative than the $70 for the riflebasix unit--although the RB unit is a great trigger.