MSP touched on this in another thread, converting a rimmed caliber barrel to a rimless caliber and the change needed to the ejector mechanizm to work properly. I had a problem getting the ejector to work well in my 35 Remington rechamber from 357Max. As MSP learned, the difference in rimless and rimmed ejection is the presence of the lifter button on rimless ejectors, without it, the ejector doesn't drop down below the cartridge rim and hangs up of the back the the rim when closing the action.

MSP pioneered the change after talking with Gordon at H&R CS, all that needs to be done is drill a 1/8" hole in the spring seat of the underlug where the latch spring is and installing a lifter button in the hole which causes the ejector to lift up behind the rim so it will eject when the action opens.

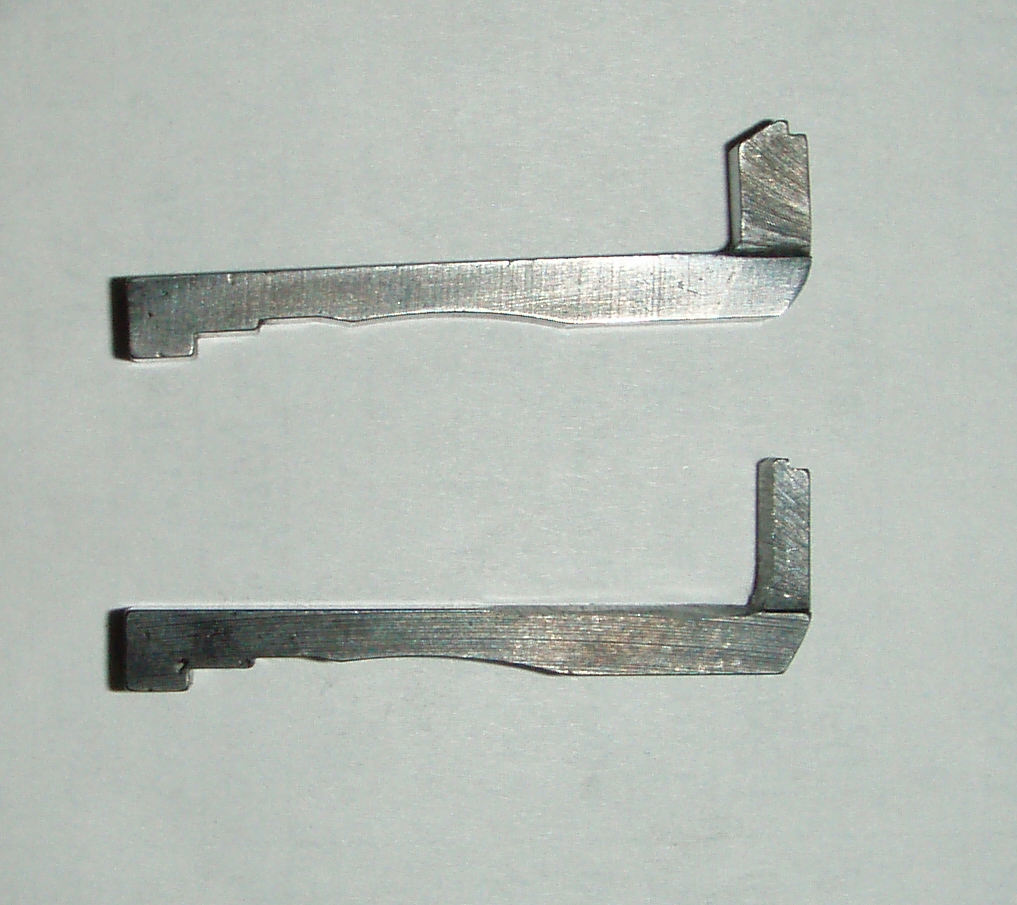

I performed the change today but ran into another issue in that the post or vertical part of the ejector isn't the same on all rifles, it's much thicker on some barrels, about twice as thick, the thick one won't work in a barrel designed for a thin post ejector. The top ejector is a .270 Ultracomp ejector, the bottom a .223 ejector that I used in the 35 Remington before I installed a .30-06 ejector today that I ordered from Brownell's when I originally did the ejector work.

Hope this helps someone in the future and a big thanks to MSP for enlightening me!!

I've added this thread to the FAQs in the ejector work section.

Tim

The lift button is the small hat shaped piece above the small latch spring on the right. The lift button can be made from a nail, dimensions are .170" long, the head is .026" thick and .209" wide, and the shank is .121" in diameter. It can be ordered from Brownell's, part #427-400-461 $4.58.

The lift button is the small hat shaped piece above the small latch spring on the right. The lift button can be made from a nail, dimensions are .170" long, the head is .026" thick and .209" wide, and the shank is .121" in diameter. It can be ordered from Brownell's, part #427-400-461 $4.58.

Lifter button hole at the end of the paper clip. This is a factory drilled hole that's off center, the one I drilled is perfectly centered in the seat!! This is a barrel I'm working on with a different kind of shim to fit it, more on that later.

Lifter button hole at the end of the paper clip. This is a factory drilled hole that's off center, the one I drilled is perfectly centered in the seat!! This is a barrel I'm working on with a different kind of shim to fit it, more on that later.