THANKS MATT ! I'm glad to see GBO back.

I'm a little confused about the configuration of the base for my mortar.

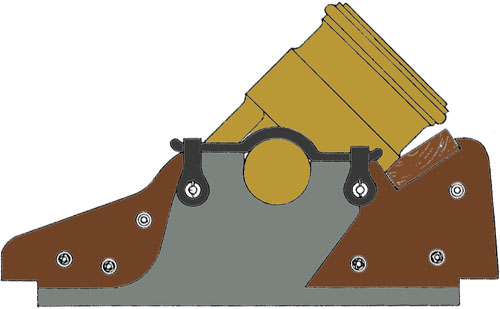

Looking at the drawing George posted, I think that Cannon-Mania's 1" "Yorktown" has the metals & woods mixed up on their base.

I cropped this from a pic posted on GBO:

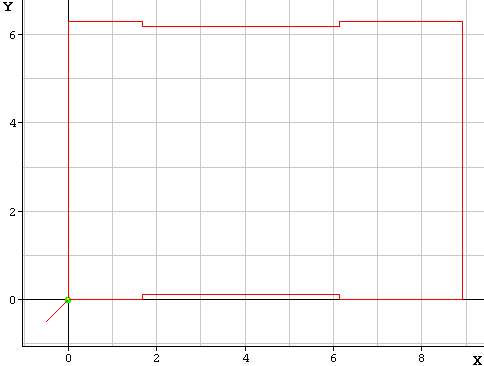

And this from the drawing:

I colored in the drawing. Gray & Black would be Iron, Brown is Wood and the Barrel in Bronze. I do believe the brass caps on the CM are 180° out (If they are to replicate the Iron cheeks as described in the drawing)

My plan is to use a chunk of 3/8" steel for the base (6.25"x8.875") with notches to accept 1/8" steel cheek plates that I will weld in. I made a CNC torch table once, and I would use it to cut out the pieces. Below are images of the CNC files in a simulator window:

(The torch has a .050" kerf, so the drawings are of the cut lines rather than the outline((a little smaller))

These, along with wood cheeks and cross pieces would make up my base. I was going to inlet the cheek plates into the wood, so the sides would be flush. I plan on using 2" stock for the sides, routed and thinned to 1 1/2" at the trunions. Cross pieces at 2 1/4" would give me the overall width of 6 1/4"

Any thoughts ? Any input will be greatly appreciated. Thanks, MIKE