This project hit overdrive this past week. The mortar was to be used in a reenactment. Ive known about the reenactment for a while but it still crept up on me. The mortar is operational but rather rough. It did not end up being used in the reenactment. Since I only had fuse for ignition the safety officer didnt feel comfortable having it on the field. A lot can happen while the fuse is burning. I agreed completely. He did inspect the gun and help me test fire it. He though I had a very sound gun and said that it would be a fine piece once I got the finish work completed.

Here are a few more building photos. I would have had more but I didnt have the time to take them.

Here are all the parts ready to be welded together.

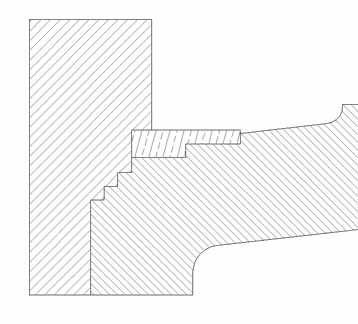

In order to preserve as much wall thickness as possible I came up with a system of steps to fit the trunnion to the breach of the mortar. I strayed from my original plans due to some dimensional differences but the general design is the same.

Here are my ugly welds. A little grinding will smooth everything out.

It doesnt look too bad. A little more work and Ill have a nice mortar.

For those interested the total weight is 125 lbs