I know the fore end can be trouble some on some guns. I thought maybe this modification would help and probably would not hurt. The thought was to put some pressure on the fore end by installing a spring and plunger through the plastic for end spacer to bear on the receiver. This would put constant pressure at this point. It should be repeatable every time the gun is put together. It is reversible by removing the plunger and spring. It can also be adjusted to put more or less pressure in this spot. I hope the following instructions and pictures will make this clear.

Parts list

1 spring about 1 1/2" long X .310 OD wire Diameter ~ .048"

2 #6 X 1 1/2" wood screws.

1 package of license plate nylon screws.

I bought the supplies at my local Hardware store. If I had a lathe, I could have turned the button out of round stock instead of using a license plate screw, but I am tool challenged so I get by with what I have. That will change some day

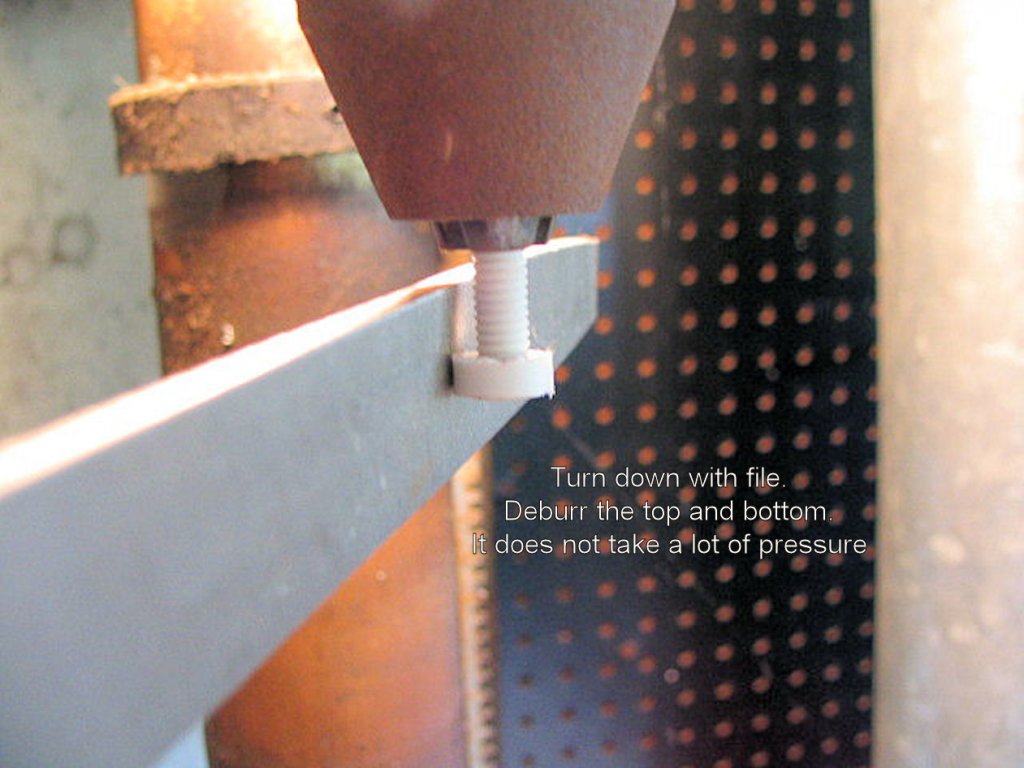

The first thing I did was to turn down the head on the nylon screw to .340". It does not take a lot of pressure to cut the head with a file, just take your time and clean the file periodically and check the head diameter.

This is so it will slip in a 3/8" hole, you will see later.

The turned down head compared to unturned head

The next thing I did was to replace the screws that come with the fore end with the #6X 1/1/2" screws. I did this so they would not strip out with the spring pressure pushing against it while off of the gun. I used a ratcheting T-handle and did not drill a pilot hole. You might want to do a pilot hole to make sure the fore end does not split out. Do not over torque the screw, it might break off or strip using too much power. Do not use a powered screw driver - you do not want to strip out this deep hole or worse break the screw off.

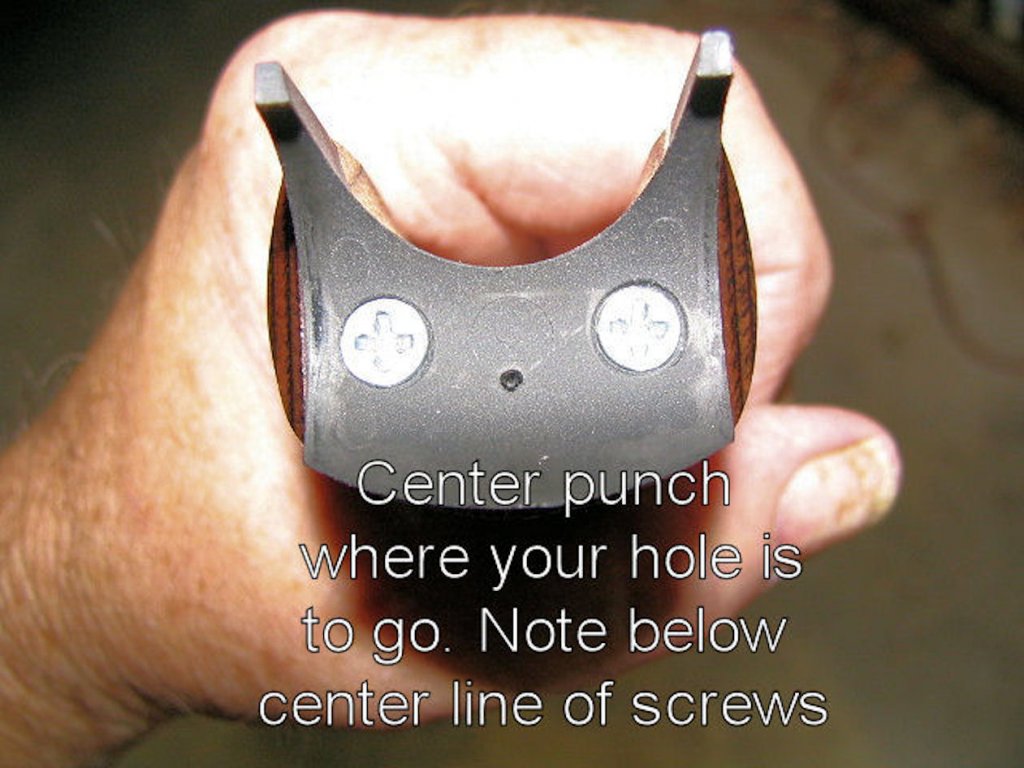

Next I put a center punch in the spot where I was going to drill my holes. This has to be below the center line of the #6 screws so that it will come to bear on the center rib of your SB2 receiver. If you get it too high, it might miss the front of the receiver and/or drill out through the top of the fore arm.

I drilled a pilot hole through the spacer and into the fore end. The hole depth will depend on your spring length. Make it a little shorter that the spring. In this picture I said 2", but I really went about a 1 1/4". Keep it as square as you can with the face of the fore end.

This shows the spring in the hole. After drilling the pilot hole, I drilled a 3/8" hole about 1 1/4" deep. The spring sticks out just about a 1/4". You can vary this dimension depending on the spring you use and how much tension you want. Remember you are going to have the depth of the head under there too. This adds a little more spring tension.

This next picture shows it all going together for a test. I have already drilled a 1/4" hole through the spacer. Vary this depending on the screw you use. I put this together to decide how much of the screw I want to cut off. I marked the screw where to cut. I took it back apart and cut the screw off with a hack saw and then smoothed up the end so it had slightly rounded edges. See how the button (former screw) head will fit into the 3/8" hole?

This picture shows it all put together. The button sticks out about 3/16" or so.

You can vary the tension by using a heavier spring or shimming under the one that is there. You can decrease the tension by using a lighter spring or clipping a coil or two off. If you decide this is not going to work, all you have to do is remove the nylon button and spring and it will act just like it did before. It does not take very long to do this. It took me about 1 1/2 hours, but that included gathering up the tools, drill bits and taking pictures. If I had it all together to start with and did not take pictures, you can get it done in 30 minutes - easy. Good Luck and Good Shooting.

edit - According to my digital bathroom scales the pressure it takes to depress the plunger is 7.4 pounds. Not a lot but should be repeatable.