This was my first and I discovered how involved it is to build iron work. The pieces are not exact copies of the originals but they are a fairly close representation, I think.

Dom,

The iron looks good. What scale are they?

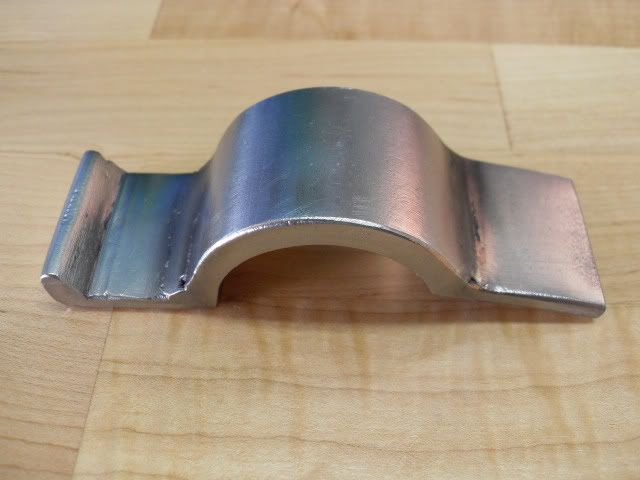

I have to agree, the iron work is a PIA.... Below is a set I'm working on for the 1/3 Parrott you made for me. It takes a lot of work! It's even worse since, I do not have the proper tools to do it. Basically, it's been a hack saw, hammer and vice. I do have a small 120v welder but this is about the max this can do.

The cap square shown below took me a day to get to that point. Also, the "button" hardware for the cheeks was originally a hex head bolt that had a run on my 1" belt sander then attached to a piece of allthread.....