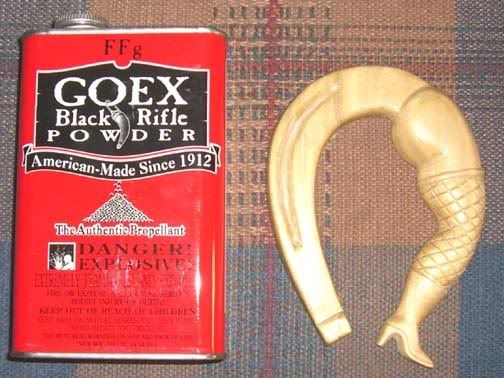

I've been trying to get my foundry operation up to the point where I can melt brass and bronze's. I do a lot of practice stuff in the form of trinkets and gifts for christmass. This year I'm planning on keychains with the family name on them. One of the trinkets that I have recently worked on is called a horeshoe. They were rumered to have been used in brothles of the wild west to let customers hnow if a room was occupied of not. I carved this pattern from a picture that I had of one. I've included a powder can for size comparason.

I was trying out my new burner and I started with aluminum. I had half a pot melted in about 15 min. My little bottle started to freeze up again and I tried running a garden hose over it. It unfroze imediatly and started running good again. Here is the result from the first pore. There was a small flaw near the top for somereason?

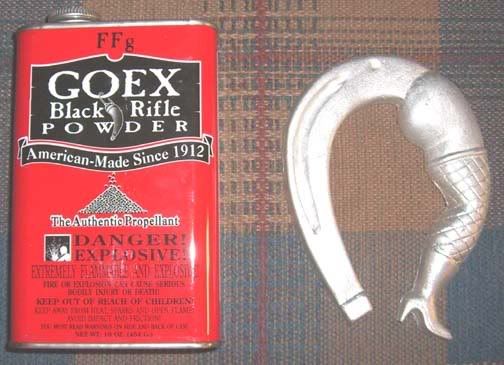

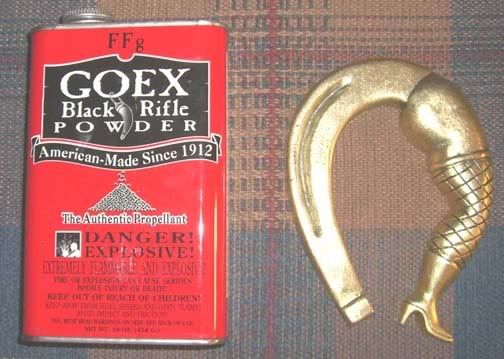

As soon as I was done with the aluminum, I added another crucible that I had to the furnace filled with brass and I went back into my garage/art studio and started ramming sand for another pore. It probably took me 20 minutes to ram up 2 patterns. When I went out to see if my brass was hot enough yet, I was very suprized. All the brass was melted. in fact I think it was to hot? the zinc was flarring off and it was hard to see the melt. I scraped the dross off the top and pored my brass. Here is the result.

It looks like I need to be carefull not to get things to hot now. There were a couple of porosity holes on the surface on this one. I had a hard time seeing where I was poring and I started and stopped a couple times. I think this caused it? It also might have been caused by my brass no being clean?

I'll post some pictures of my burner here later today. It worked very good. Also that regulator I have goes up to 35 Psi.