Hello,

It's nothing fancy.

Just used a flat piece of steel. I used an old wrench because it's tool steel.

A hand grinder makes the process easier, but keep in mind that all the fine work is done with small files. You will need a drill to make the hole, but that's it.

Start by taking the old part out. The pin (at least on mine) drifts up from the bottom, out through the top.

Cut an "L" shaped piece of metal of approximate size. A hand grinder with a cutting wheel attachment comes in handy for this.

If you've ever had one of these out, you'll see that there's a "tail" that the spring rests against. A hand grinder with a fine grinding stone attached makes one of these nicely.

I found that holding the new piece in the bolt and smacking it through the hole with a punch gave me a better location for the pin than did the old piece.

It's very important that you fashion the hook by hand. Those grinders can get away from you.

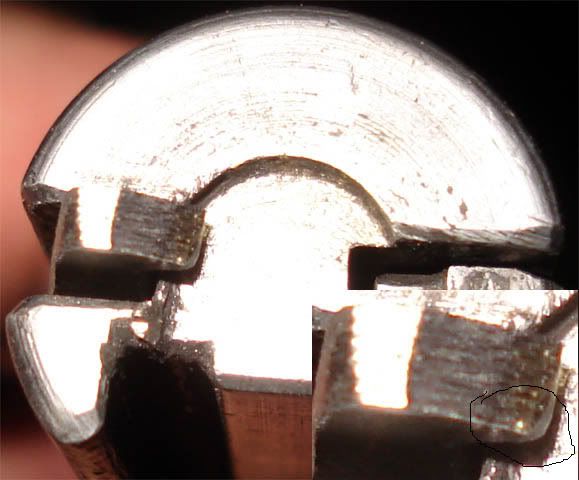

Notice the circled part.

Notice the circled part.That relief is very important to feeding.

Play with the height of the claw as well as its reach across the bolt face.

Play with the height of the claw as well as its reach across the bolt face.The hook should just hold a shell on. Remove the extractor, take a couple file swipes, then try again. I can't stress enough the importance of a sharp hook; it's critical to ejection in these. If you work slowly and get the hook and tension just right, you'll have nice, strong ejection compared to the usual weak ejection of the original extractor setup.

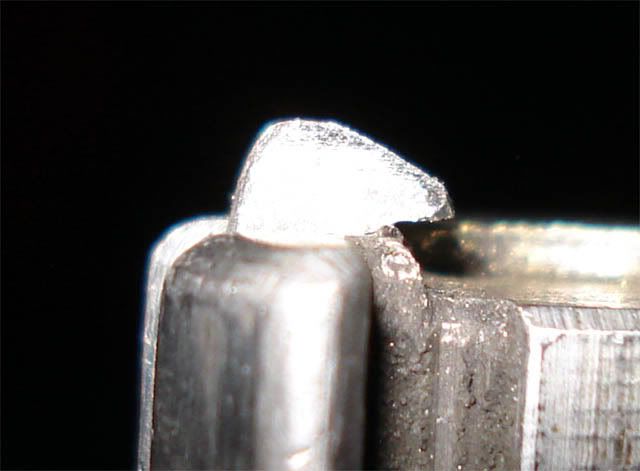

Side view.

Side view.It's also very important to get the side recessed into its groove. If you don't, it will hang up on the receiver wall when you have a shell in it.

Altogether, plan on spending 6-8 hours on this project. It looks easy, and it is for the most part, but the final fitting really takes a lot of time.

Thanks,

Josh <><