I just got my forend fitted and wanted to share my experience.

I have boyd's brown laminate thumbhole and they don't make a matching forend so I modified one of their heavy rifle forends to match.

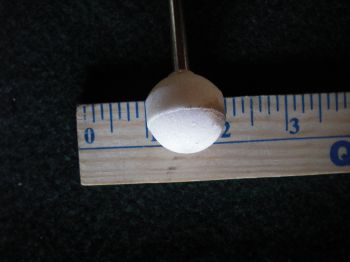

When I ordered the 20ga slug barrel from Ed's I also got a synthetic forend to help me match it up.The first thing I had to do was countersink where the 'drift nuts' are to be able have the forend touching the barrel, the size of the hole just has to be larger than the nylon washers to be used and flat, the depth just has to be deep enough to clear the 'drift nuts' for now. I used a grinding ball to clear the wood from the channel, I was surprised by how little had to be removed to have the barrel fit right.

The synthetic forend had large head screws so I went with allen head screws (#10 x 32 I think). The existing hole had to be reamed out, I used a 3/8" forstner bit. Only drill to where the old screw heads sit.The final size of the screws will be determined by how much wood is removed and the thickness of nylon washers used. I had to cut and grind multiple times.

I used epoxy to glue nylon washers into the countersunk holes. The front hole is shorter so be careful how much is countersunk underneath, you want to have enough wood to hold it on. I used a nut on a longer allen screw to clamp down the nylon washer then when that dried used more epoxy around the washer to keep it in place. Then used 3 coats of satin exterior urethane on all the places where finish was removed to seal it up, It matched up pretty well. As you can see these holes don't have to be perfect they will be hidden when all is done.

The only other thing I had to do was knock one of the 'drift nuts' to one side so I was able to slide a piece of paper between ears of the forarm and the frame, I am able to slide that paper all along between the barrel and forarm except where it is fastened, I guess it is as 'free floated' as I am going to get it.

Here it is all together.