What did you use for material to start with, and what diameter is it?

Rickk!

I just took some metal bar that was lying around, so I don't know its composition (at least it is no stainless, so brittleness shouldn't be a problem). Its diameter was originally 10 millimeters (a little more than 3/8th). When you look at the pictures, you may see, that I actually missed one reinforcing band. But it was somewhat difficult anyways, to get the dimensions close to the original design. Remember: This was done (as well as the mortar) without the luxury of using a lathe.

How you gunna attach the trunions?

With the trunnions, due to the size of the piece I need to do some compromises:

What I am concerned is, when I drill into the barrel to fit the trunnions into it, that will decrease the wall thickness at this points substantially (especially true due to the 60 degrees tip of each common drill):

Where the trunnions should be positioned, the wall thickness is just about 2 to 2.5mm (5/64 inches to a little more then 6/64th) the trunnions are about the same diameter, so if I would drill into the barrel at this point, the remaining wall thickness would be close to none.

Therefore I will leave the barrel like it is and file the corresponding surface of the trunnions to fit the outline of the barrel. After that I will glue them on with epoxy.

From the standpoint of stability I would always choose welding before soldering, before gluing: but in this case it is just too small to do so.

To catch up with recoil, the barrel will be welded from the bottom onto a steel plate that is located at the end of the carrige. The sides of the carrige are to be made from wood (beech) that has just 3/4th of its final thickness. Then I fix those "boards" with metal screws to the bottom plate and glue the remaining 1/4th ontop of that, so the screws will be invisible. The rest of the carrige will be done out of wood as well, so basically that metal plate is invisible.

I know that this is just a mean trick, but I would rather go safe than to be closer to the original design (this "gun" shall be fired, not just looked upon). With the small dimensions of the piece it is not possible otherwise I guess.

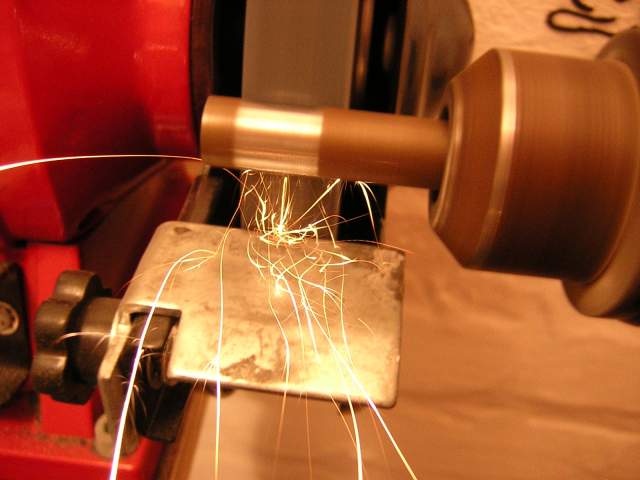

By the way: it is nice to see, that we came up with nearly the same procedure to get rid of excess material:

But I used a grinding wheel and did fit the barrel-to-be into a drilling machine (moved by hand) that rotated in the opposite direction.

Merry Christmas to Everyone!

Merry Christmas to Everyone!