Well it's been an interesting few months to say the least. I am back into working on all 12 of my ongoing projects! I thought I would post up some info on a couple that might interest all you great guys here. A while back you may remember my golf ball caliber carronade that I built for our wedding. Here's a really crappy pic of that event. Its a picture of a picture behind glass with a hand held camera. I'm too lazy to scan the picture right now. LOL!

I'm the one on the left that looks like Butterbean's little brother.

I posted some better pics in the calender thread up top. I will be doing another photo shoot with my cannon's real soon, I need some new ones of this cannon since I added a few embellishments.

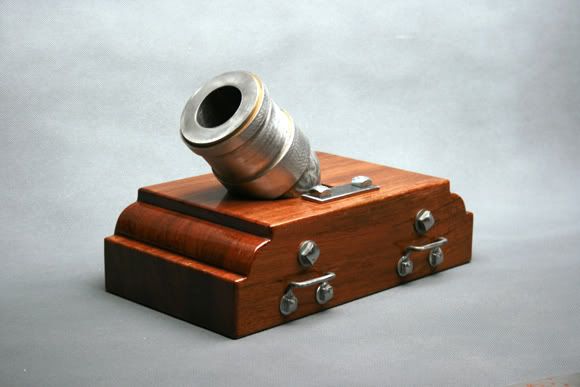

Here is one project I started a while back. It's a golf ball bore Cohorn mortar on a Jatoba bed to match my cannon above. I am waiting on some parts for a gun, then I will parkerize the whole lot to match the cannon.

It's coming along but I think I will be making new handles. I'm not happy with these.

Here is the other project I am working on. This one is a golf ball caliber Dictator. I have had to stop and make some tooling for my lathe to turn the barrel and waiting on the materials and various supplies slows the progress.

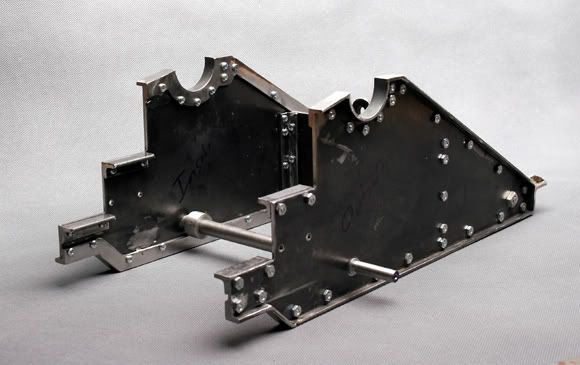

This is the steady rest I built.

It will support this 62lb chunk of 1018 ( I hope) The small piece welded on the end will go into my four jaw chuck to spin it up. This will take some time to machine and will certainly max out my little lathe.

I have added a counter shaft assembly to the lathe to slow it way down and am in the process of converting it to a DC motor with a speed control. All I have to do then is make a boring bar holder to attach directly too the lathe cross slide then I will be ready to start on the barrel.

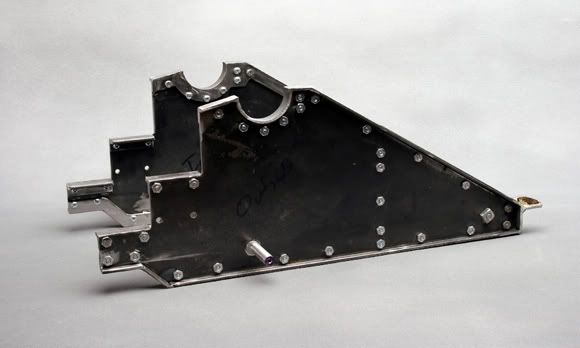

Here is where I am at on the steel bed.

I will post more pics as I progress if anybody is interested.