Greetings,

I am new to this forum. From my review of this forum there seems to be a great deal of experience amongst you all so perhaps some of you have seen this before and have some answers.

My Ruger Old Army is almost new, (it came to me barely used without box or manual), but has an annoying habit of releasing its loading lever from the frame when I am compressing the balls into the cylinders. I can actually watch the retaining screw turn "by itself" when I try to compress the ball into the cylinder.

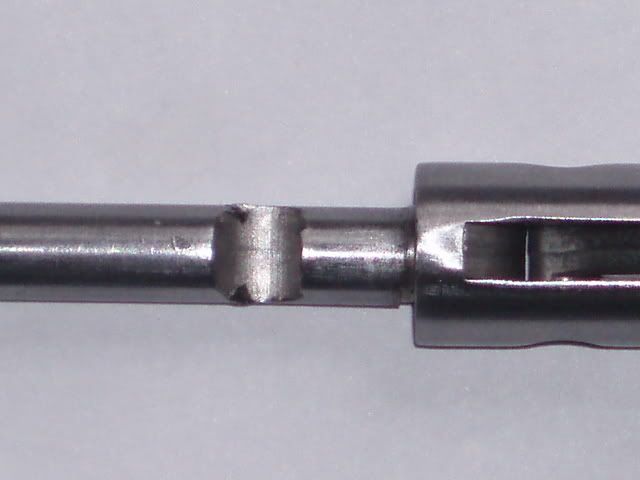

I disassembled the loading lever and discovered that the loading assembly rod, ( the longer narrow one), has a notch cut out to receive the frame retaining screw. The general shape of this cut out is a "half moon". You may be able to see from my pic's that the shape is actually a partial half moon. One side is "squared" instead of tapered like the other side. Is this a machining error?

Also note the damage to the rod cut out where the retaining screw makes contact. This is from me adding extra pressure to the retaining screw trying to make it hold fast while I am loading the cylinders.

The retaining screw can only be turned 1/3 of a turn "clockwise" after inserting the rod and until it "locks up" or contacts the rod half moon" cut out. I would think it should be able to be rotated more, maybe 1/2 turn so its body would fully engage the rod "half moon" cut out. Of course on my gun this is impossible because the partial half moon cut out doesn't give enough room for this to happen.

My current working theory is that the cut out on the loading rod should be a perfect "half moon" shape. What shape is yours?

Edit, update: I just discovered that by pulling the rod out a 1/16th I can turn the retention screw counterclockwise 1/4 turn. This seems to hold the loading lever when I apply force to the cylinder wall simulating loading.

Question: Is the correct direction for turning the frame retaining screw counterclock wise?

Second problem:

The gun takes two hits to fire. I have tried CCI 10 and 11 caps. I simply cannot believe that two hits is normal for a gun with such a reputation for quality. Have any of you experienced similar ignition problems? Are you all using the wooden dowel system to press the caps on? This doesn't seem like this step should be would be necessary given these guns worked with the old technology and we presumably have made technological advances since these guns were first used.

Thanks for your help in advance.