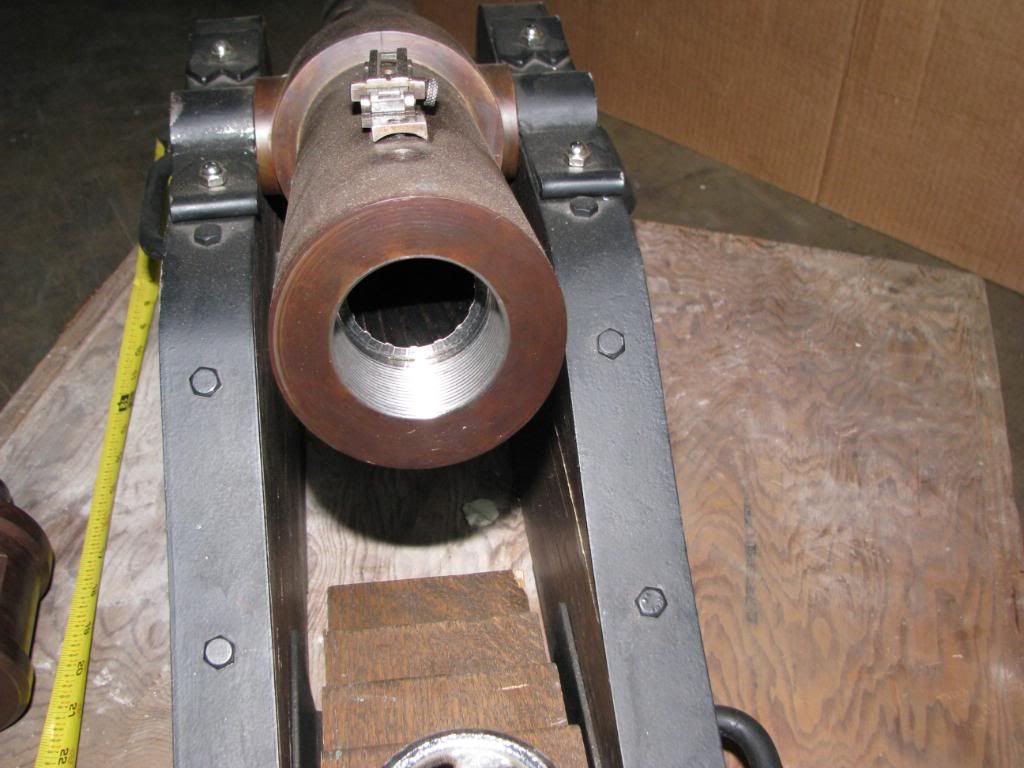

Here's one way to help seal the breech. Make the cannon with a seating surface at the rear of the chamber as you can see in this cannon, made from a 40MM Army cannon barrel. If you want to do more to prevent any gas leakage, the simple addition of an O-ring or whatever your favorite kind of gasket is, should work fine.

We've fired this one many times and havent' had any noticeable gas leakage past the threads, so we haven't bothered to put any other kinds of sealing in place. We haven't had any powder fouling of the threads either, so maybe the system "as built" is good enough.

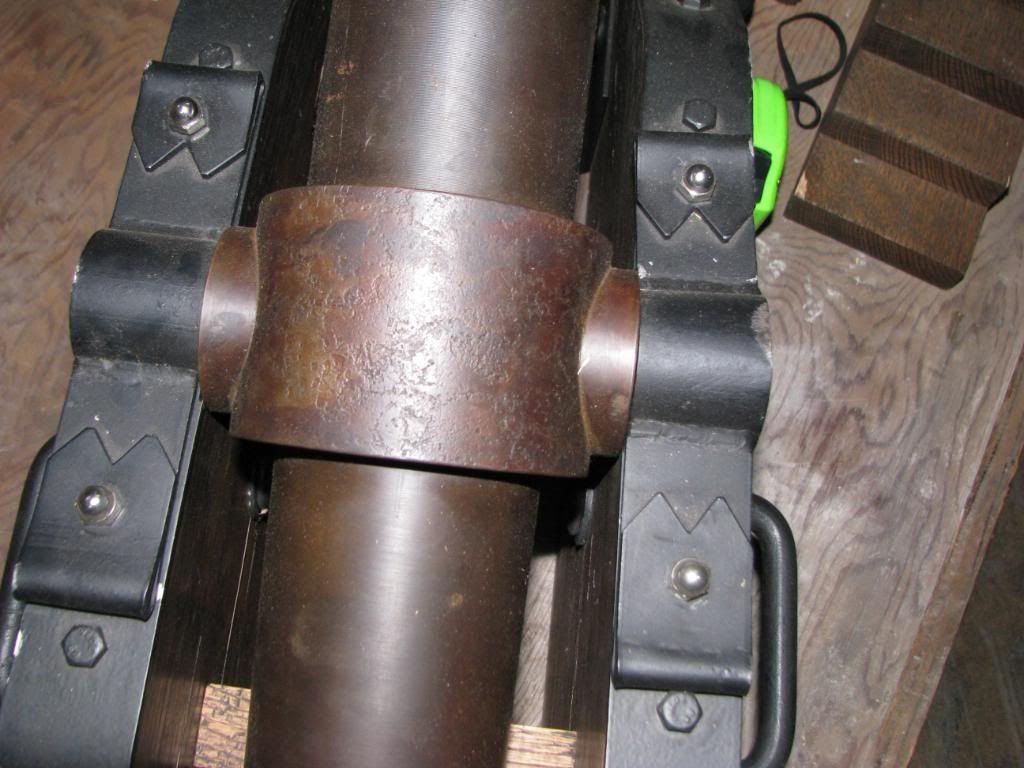

The carriage is home-made out of oak and hardware store stuff. It is pretty much an exact copy of a USLSS "Lyle" gun carriage, except for the elevating screw.

My friend Ed (the "star" of "cannonmn" videos on you-tube,) who built this gun, shoots various projectiles in it. One type is the rear half of a Navy 40MM projectile with copper rotating band removed, and replaced by a lead band he epoxies on in the knurled groove left when the original band is removed. He buys lead sheet or strip that fits the groove somewhere, and wraps it around a couple of times until the rotating band it forms is the correct diameter. Cast lead projectiles work well too. He has used a short, separate section of the rifled 40mm barrel to cast lead projectiles, so of course they come out of that mold already rifled. The adjustable rear sight is from a US Krag rifle ca. 1898. The front blade sight is also some kind of rifle sight, I've forgotten exactly which weapon it came from...

Since my company is now a sponsor I guess we can say that we sell 40" lengths of this type cannon barrel for $399. plus shipping, or one 20" length for $249. plus shipping. The bores are new, unfired, and usually still have cosmoline in them.