On to the hubs.

I made the bands first. Thought it would be easier to cut the hubs to fit, in case the bands were a little off.

The first two shots are of the bender. Looks like nothing to it. Well, the set up directions have a little bit to be desired.

The next one is for correction. A little huff and puff and heat and hammer. They worked.

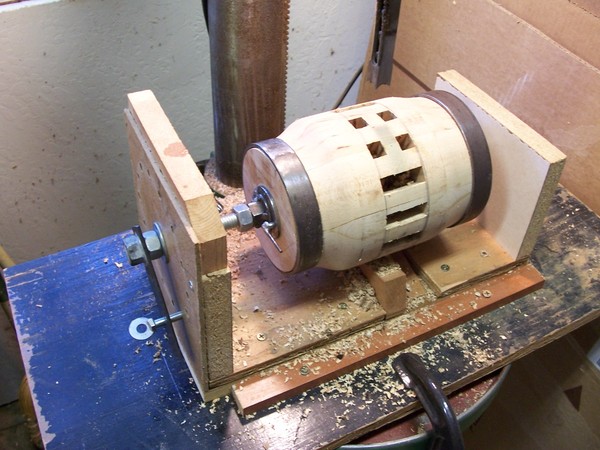

On to the mortising tool. I only have a couple pictures, was a little busy that day. The jig that's holding the hub is the one I used on my 5th scale carriage. I did have to extend it a bit. The first row of outside holes had to be tapered 6 deg. for the dish. That was done by tilting the table. The inside row was straight, the same with the middle row. This setup has to be rigid, it takes a lot of pressure to bore those square holes into oak. You can see that I had to shim the bottom of the hub to take out the flex.

Well that's about it for me. I'll have to start pondering Max Caliber's suggestion with the metal lathe. Get back to you when I have some more.

Ron