I've been a troll here for several years, but just signed up as a member.

I'm looking to create a golf-ball mortar that should look nice and shiney while being functional.

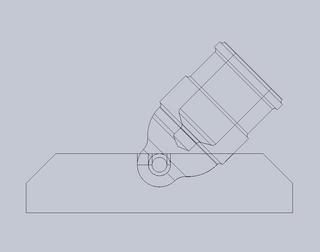

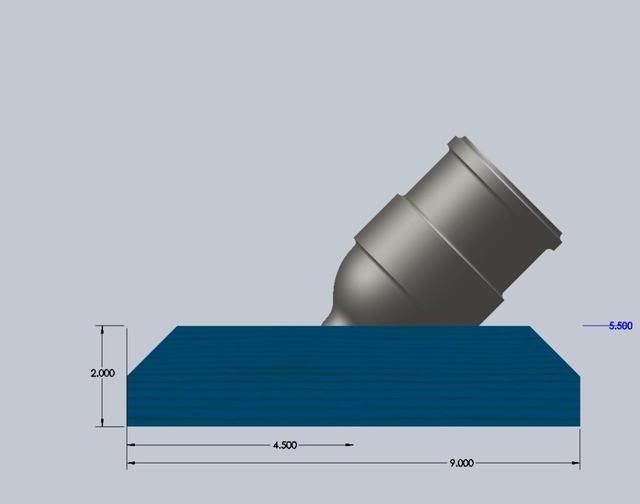

Its a bit modified from a "normal" mortar as I have modeled it so the trunion is completely surrounded by the chamber end of the barrel. It is loosly based off of an EZ build listed on this forum.

Bore is 1.7" I.D. with a depth to powder chamber just under 2xID

powder chamber is .75" I.D. by .75" deep.

fuse hole is 1/8" diameter

trunion is .75" O.D. and 4.5" long.

Maximum O.D. of barrel is 3" with narrow bands at 2.75" I think, don't have cad at home.

bed has cavity contoured to match barrel set at 45 degrees.

Bed, right now is 2"x9"x5"

I will probably make the prototype out of 1018 or 1020 steel. I would like to make the gift versions out of stainless steel or bronze so they polish up nice without worrying about rust. Stainless steel is very easy to find as scrap around here so I'm leaning towards that but have not researched or desided if I like the material for a "cannon". I know Marlin make a good many 45-70's with SS receivers and breaches so I know it's possible. I will end up laser etching information on the muzzle of the barrel and if possible on the top of the barrel.

Any tips/comments on changing the design for the better would be nice. I haven't figured out what length handles I want on it yet. I'm pushing for 3" wide so they are functional.