Just about this time last year I bought a sleeve of 150-grain bullets for my 270 Winchester, Remington 760 pump. The intention of the purchase was to have bullets for practice at the range. Nothing against the Winchester Power Point; I found it to be very effective on deer.

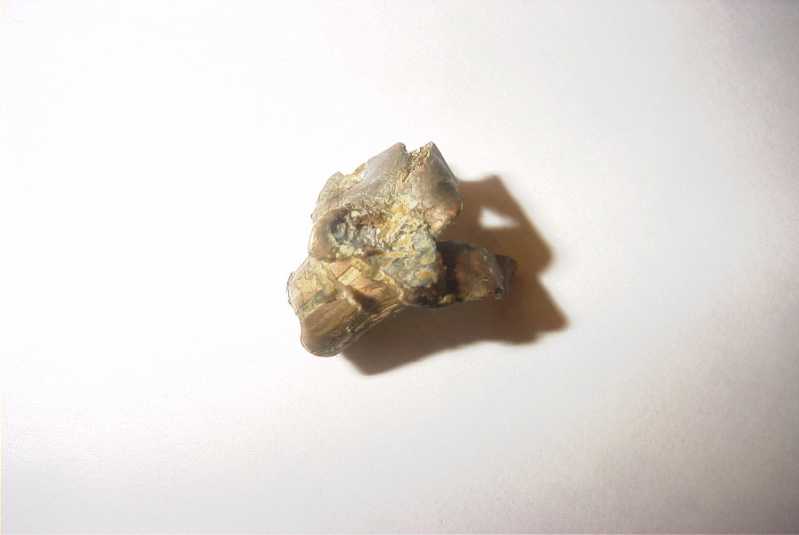

This one I recovered from a buck I shot at just over 250 yards, it was a factory loaded round.

For this session I resized G.I. 30-06 brass down to .277 for the 270 Winchester. I checked the resized brass in the 760 and it chambered without a problem. I used CCI200 primers to lite the 56.0grains of H4831. The load average 2831 fps across the new Beta Master Chrony my wife bought me for our 46th wedding anniversary.

The target represents 11 rounds.

A few weeks before I had put a round from my 357 Magnum into the face of the Chrony she had bought me for Christmas 13 years earlier. But that is another story. I solider a wire back together and it works. Poor thing flopped on the ground and started flashing Err….

When I returned home from testing the rounds over the “new” Chrony I resized the same brass, used the same primer-powder combination, and pulled bullets out of the sleeve in the order they were presented.

I did notice that a couple of the bullets required a little more effort to seat, but not enough to set off alarm bells. The Lyman Mag-T II press has a lot of leverage. I might have notice more with the old Spar-T press which does not have near as much leverage.

The goal on this last trip was to check the loads out at 200 yards, and come up with some experience using the 200-yard ballistic line in the scope with BDC crosshairs. The first rounds functioned just right in the rifle, then I had one that failed to chamber properly, and lack about a ¼ inch of fully chambering. It required extra effort to eject the round. I fired two or three rounds and had a second round stick.

I packed up the rifle and remaining loads to be examined at home and continued to shoot at 200 yards with another rifle.

At the reloading bench I broke down the problem rounds and pulled out my digital calipers and started out measuring the cases. I could not find a problem there. But when I measured the bullet diameter the problem became apparent. The bullets in the problem loads measured .284/.285.

I measure miscellaneous .277 bullets I have on hand and they measured .276/.277/.278 with the majority measuring .277. I have a few boxes of factory loaded WW 150-grain PP and they measured .277 above the cannelura.

I called #2 brother who bought a 1000 bulk WWPP 150-grain .277 bullets from Midway years back and asked him to measure some of those bullets. In a return call he told me they measure .277.

I should note that I do not have any .284 Power Points in my inventory. I did have two sealed boxes and traded them to my brother a few years ago. In return I received 160-grain Speer spitzers.

I started pulling remaining bullets out of the sleeve, I ended up with 12 bullets including those from the broken down rounds that measure .284/.285.

I bought some additional bulk bullets from the local dealer. A couple hundred150-grain Remington CL for the 30-30. I will be measuring them before loading.

I bought a few hundred blems from Mid-South, they are 130 grain Hornady SST; A very accurate bullet. I am spoil by the consistency of the bullets I purchased from Mid-South. The only problem with the purchase was that I did not order a thousand. But that might have caused problems with the banker.

P.S.

I did not repair the old unit until the new Chrony arrived. It is now my pistol Chrony.