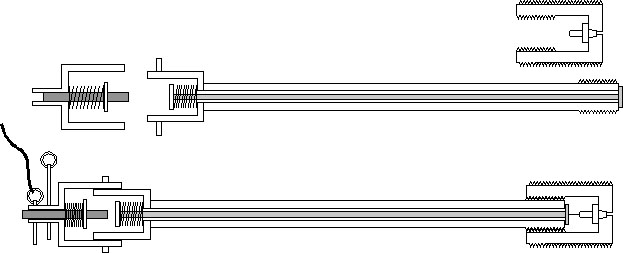

OK how about plan G for a firing mech.

This would use a percussion cap on the nipple that's seated in the head of the gizmo at the right.

The head would screw onto a firing pin section, the long tube, and then would be inserted and screwed into the bottom of the powder chamber.

Then the hammer section would be attached which has two pins, a safety and a release. It attaches to the mid section like a tail light bulb in a car.

When ready to go you'd attach the hammer section to the back of the firing pin section and when ready to fire the safety pin would be removed.

Then pull the rope to the release and BOOM.

This is a rough sketch to get the mechanics of the thing down on paper and will need a redesign since it'd be a pain if the head stuck in the chamber and the firing pin section unscrewed leaving the head behind.