Indy,

Wait for your barrel.

When I ordered mine from South Bend, They gave me the trunnion measurements on the phone. I decided to wait. When the barrel arrived, the trunnion diameter was a different measurement from what they told me.

Concerning the angled spread on the side rails.

Here is how I do one of my naval cannons. I have a 2 1/2 degree cant on both sides.

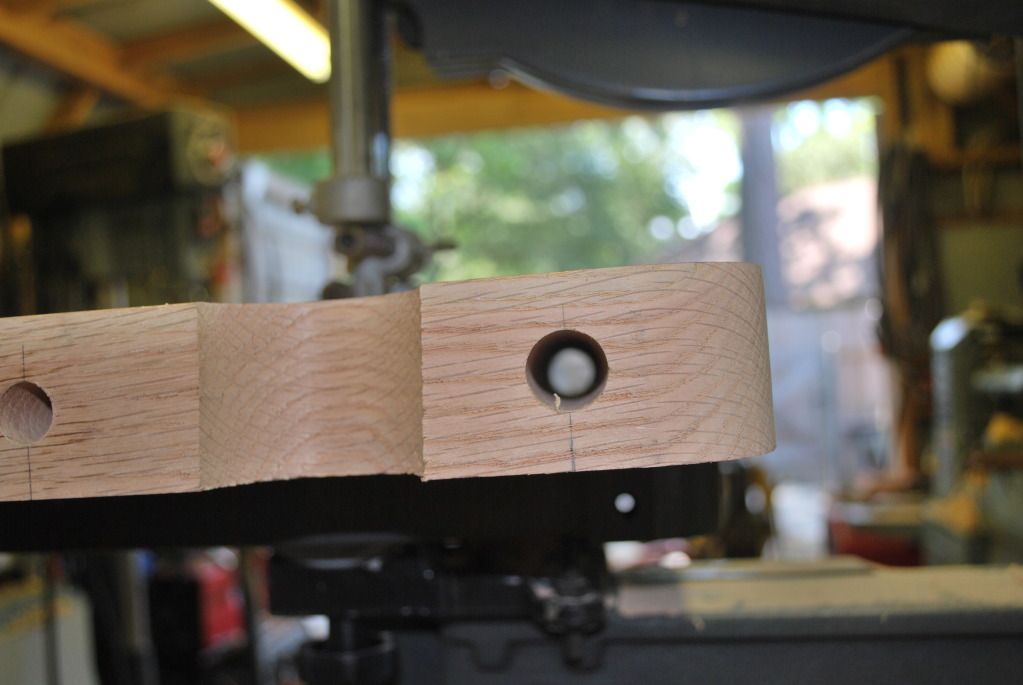

This means all drilled holes, including the trunnion pockets, have to be drilled at 2 1/2 degrees also.

I also have to make all cuts where side cheeks join to axle at 2 1/2 degrees.

If you look, you can see the angle.

trunnion pocket angle

I turn a faux trunnion on my lathe to get my measurements right.

When capsquares are made, they have to have the same 2 1/2 degree angle also.

This system works very well for me as most of the time I don't have possession of the barrel I'm making a carriage for.

I made the white field carriage as a complete novice to wood working. I had no idea how to get all those angles to work so this is what I did.

Never tell anyone this.

I drilled the trunnion pockets straight. No angle. I drilled all other holes a little oversized. No angle. I made the capsquares straight. No angle.

I used no angle in my cuts where the cheeks join the axle housing.

I put everything together and then tried to spread the rear of the trail a little. Because the trail cheeks are 5 1/2' long, it did indeed spread a little. I spread it as far as it would go and cut my side rail separators to that angle.

It worked for me.

If I had to do it again, I would never do it that way. I absolutely would do it the proper way.

Zulu