Starting on the wheel..

This is proberbly the biggest show stopper for most people building this model. 7 fellows 14 spokes to be carved out from wood can make your hair turn gray only by the thought..

I must admitt that this has taken most of my time so far on this project, and thats before a single cut has been made.

I have decided to cheat a little by cutting fellows and spokes using a CNC mill. The mill is a small tabletop sized Sherline, that I have converted to CNC by mouting stepper motors on 3 axes, and build the stepper controller from a kit. The conversion way easy, understanding CAD, CAM and CNC software is another story. Up til now I have not used it as a pure CNC machine, but used the mill semi-manual by driving the axes with motor instead of handcranking..

So it has taken me a couple of evenings to get a understanding of the sw-part of using CNC..

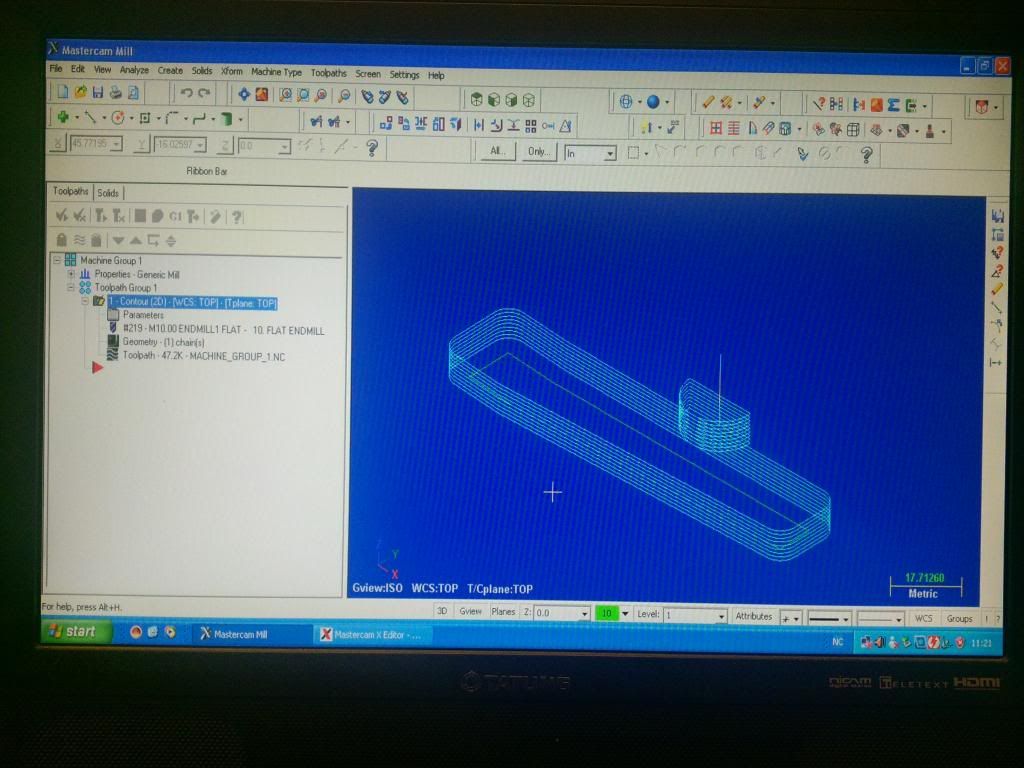

First of I started to draw the outlines in a CAD\CAM program, this is easy. The more demanding task of the software is to program how the cuts are to be made along the lines of, in this case the spokes. There are no ending to how many options there are in the sw, so a little trial and error is the only way to learn

This first picture show an isometric picture of the spoke, and the path that the endmill will follow cutting this part in 8 sequenses.

I am cutting light cuts, and frankly it could easy been cut in 2 or 3 passes..

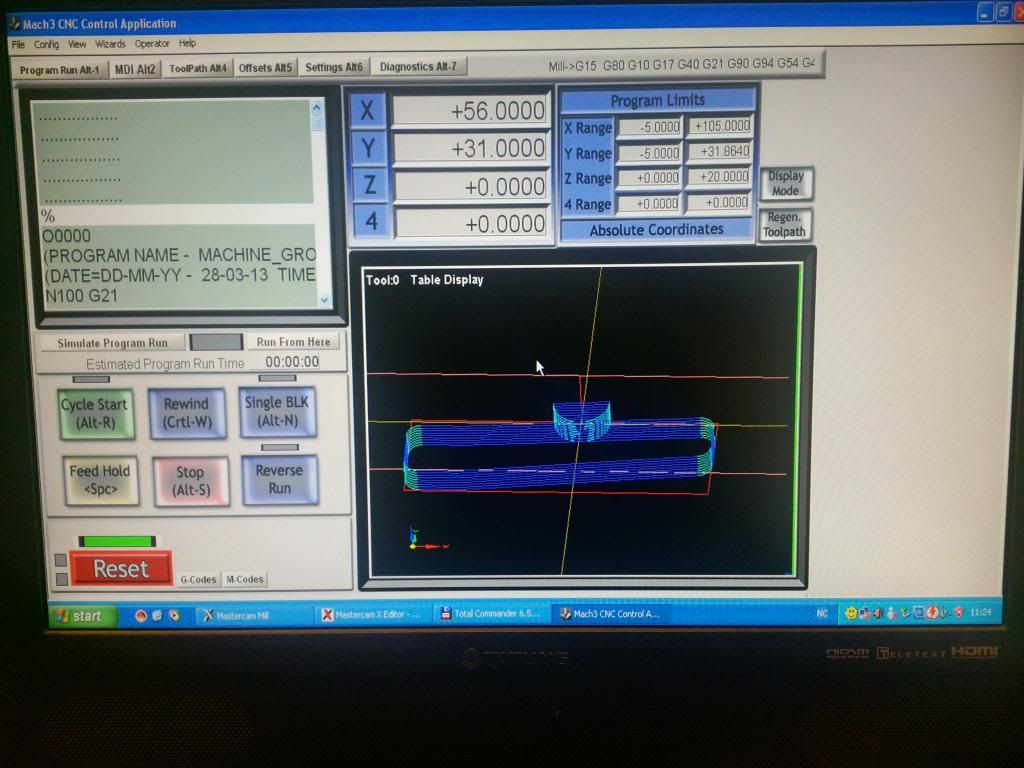

When happy with the set-up in the CAD\CAM software, the data is stored in a file that are used by the CNC- software, that is the sw that is driving the CNC directly from the computer.. Next picture is from this sw, and again here we see a window of the tool path, and the semi circle you see is how the end mill is entering and exiting the material at each step of the cut. By using a lead-in/out there is no way to tell where the mill has started and stopped.

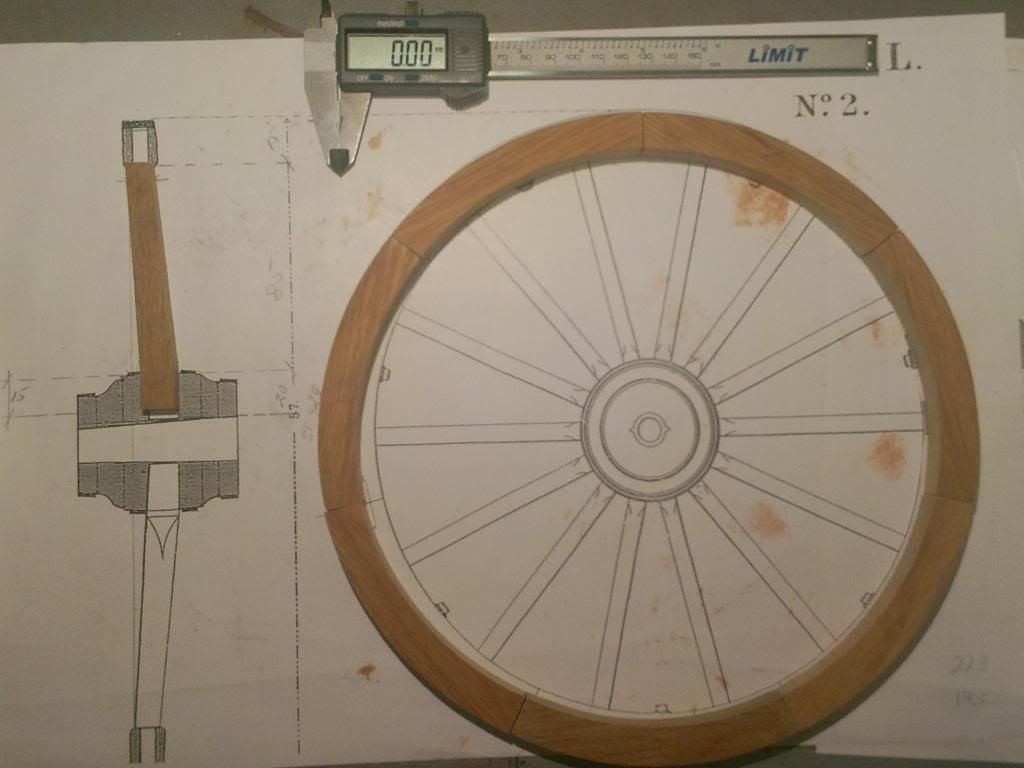

Now that the program is loaded, the material needs to be aligned on the mill. I have here a 15 mm oak piece for doing a test run to see if the program is done correctly. The spoke are to be 7 mm, so later on I need to find some thinner planks..

Here we are ready to press "play"

And some minutes later, we have a perfect cut spoke, though in need of cutting loose from the 0.5 mm material left in the pocket from the mill path. And of course, it need to be reduced from 15 to 7 mm thickness..

And here we are.. The first cut spoke blank, and some allready cut fellows.

Now, only 27 more to make

I will await doing more spokes before I have decided how to attach them to the fellows. My initial plan are to drill a center hole of 4mm at the outer end of the spoke, and drive a dowel trough the fellows into the spoke. Any thoughts on this issue..??

I also needs to come up with a plan on how to make the rounded profil to the spokes.. And decide how to make up the nave for the wheel, and how to cut the holes for the spokes. I have one radical idea, but will get back to you on that one..