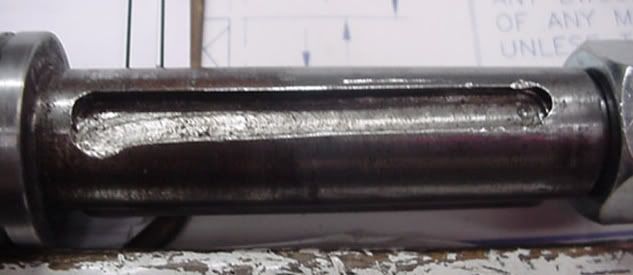

Hello, Its been a looong day. But here are some pictures. The first problem was getting the drive pully off. It took a while. Here is why. This shaft was made long ago. The shaft is OK, just the key was milled wrong.

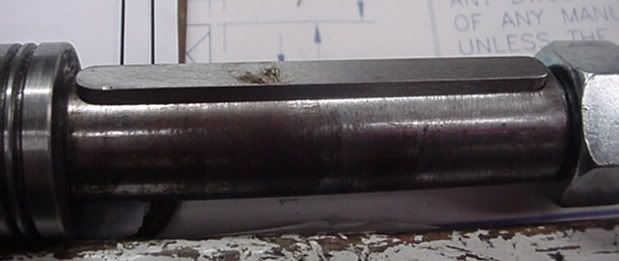

I re-milled the key on the other side of the shaft, seen here.

I opened up the headstock.

And found these lying at the bottom :shock:

Here is where they used to be.

Nothing wrong here, I'll just reinstall as is :shock:

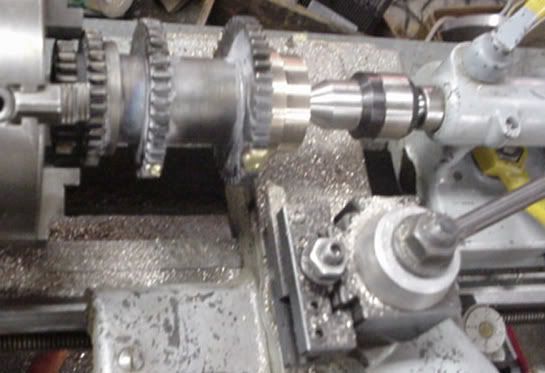

I'm going to use brass to build up my gears. To give them a stronger hold. I ground what was left of the old ones away and under cut the gear about 1/8" or so.

Here are the gears after Brazing. I just used some brass rod, with the flux on the outside, from the hardware store. I've done this before and those gears are still going strong. The red/brown looking stuff is the flux. Also notice the gear's on top. There were some chips on the corners. I'll just clean them up with a file.

I set the gears up in my little Southbend and machined the outside profile of the gear.

To be continued........