I'm getting to the fun part on these

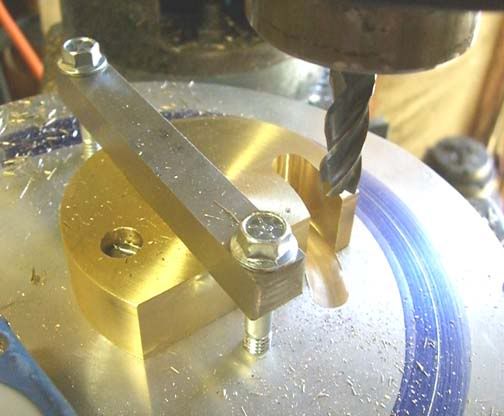

I got the flat milled and the holes drilled and reamed. now I am setting up on my rotary table to mill the radial slot that will lock over the second breech pin. I made a sacrifical table out of aluminum to bolt these doors to that I can mill into and not mess things up. Here is a picture of the settup. The first thing I did was to bolt the rotary table to my mill table. I then centered the RT under the spindle of my mill. Then I bolted the aluminum to that and centered it under the mill spindle. Now when I rotate the table the pin stays stationary. The four big holes have socket head bolts in them and bolt the aluminum to to the table the two little holes are for the clamp to hold the door to the aluminum.

The door pivot hole then goes over the pin in the center of the table.

Then the door gets bolted to the aluminum.

Then using an indicator. I move the table of the mill over a certian amount, in this case 2.000". Now when I rotate the table I can cut a slot that has a 2.000" radius. this will let the door drop over the pin. Here is a picture of the slot.

These should finish up pretty quickly now that I have my settup and jigs figured out. I have to come up with a way to hold the door to drill and mill the socket for the handle to make it easier to open, but I think I have a slick trick figured out for that. I hope my explinations make sense?

To be continued....